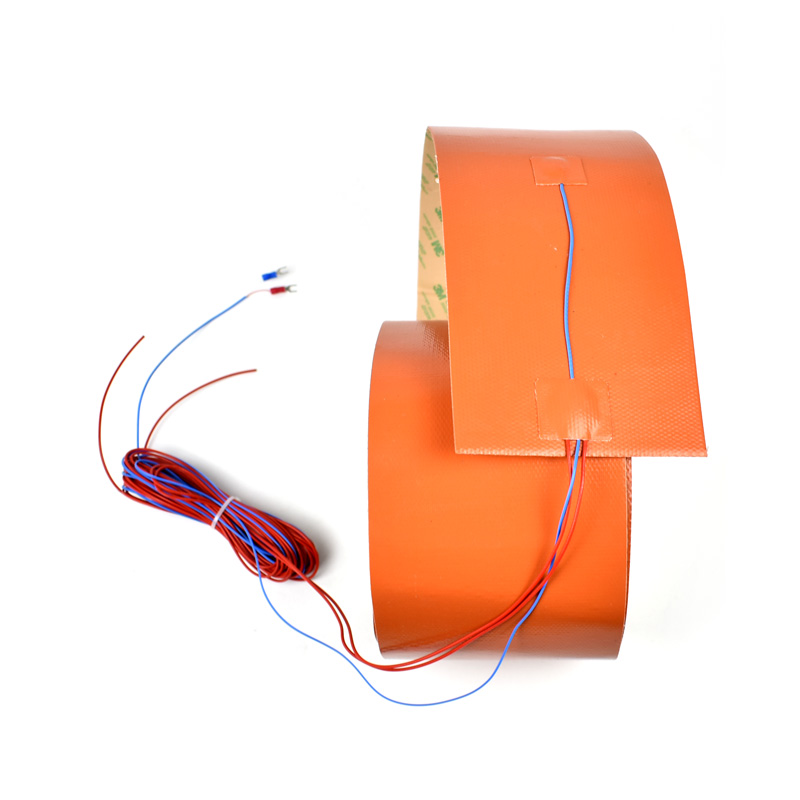

Silicone heating element is a relatively thin sheet that generates heat when powered on, with a standard thickness of 1.50 mm. The heating element uses nickel chromium wire or nickel chromium foil with a thickness of 0.05 mm~0.10mm, and both sides are made of thermal insulation material. It is formed by high-temperature molding and aging heat treatment, and has high reliability. The oil barrel heating belt adopts the soft and flexible characteristics of a silicone heating plate. Metal buckles are riveted on both sides of the heating plate with reserved holes, and spring buckles are used to fasten the barrel, pipeline, and tank body. Easy and fast installation. It can make the silicone rubber heating plate tightly adhere to the heated part using the tension of the spring, heating quickly and with high thermal efficiency. A heating system solution for low-temperature charging of power batteries in new energy vehicle battery heaters: The silicone heating system is a thin, pure resistive heating element with a soft thickness of 1.5MM. The silicone rubber heater is mainly composed of nickel chromium alloy heating wire and silicone rubber high-temperature insulation layer. The high-temperature insulation layer of silicone rubber is a thin sheet made of silicone rubber and glass fiber cloth (with a standard thickness of 1.5mm), and the silicone rubber heater has good flexibility. It cannot be compared to silicone rubber heating strips that are commonly printed on insulation materials using graphite paste, resistance paste, etc.

Technical parameters

Rated voltage: AC220V ± 15%

Rated power: 50W/75W/100W/150W/200W

Power error: ± 5%

Wiring length: 1-10 meters (according to user order requirements)

Operating temperature range: -40~200 ℃

Maximum temperature resistance of insulation material: 250 ℃

Insulation resistance: ≥ 100 M Ω

Compression strength: 2000V/min

Mechanical strength: 100kg/cm2

Ordering guide for silicone heating pads:

The shape of silicone heating pads can be freely made or designed according to needs.

The silicone heating strip is evenly distributed by alloy resistance wires on the silicone rubber insulation layer, and its shape can be freely determined. After production, it cannot be cut.

Silicone heaters can process various shapes, such as circular, triangular, and guide shapes.

Due to the different installation status, usage environment, and temperature control methods of silicone heating pads, their power density may vary greatly. Please contact our company for consultation when selecting them.